DeVo’s WoodCraft - Cutting Board Care Instructions Do’s and Dont’s

· Do not let the board sit long while wet and do not place in a sink full of water.

· This is natural wood and it will warp and/ or crack if water is allowed to soak into the board. The board conditioner will help with this.

· Never wash the cutting board in the dishwasher. Do not use in the microwave or oven or use as a hot plate.

· Use the DeVo's Cutting Board Conditioner and or mineral oil. If board is used as display only then condition once every 2-3 months. If the board is used regularly then condition after every couple of uses. More or less may be needed depending on how dry the board gets. For best long term care, use conditioner anytime the board is starting to look and feel dry.

· Oil the board completely on all sides and edges every time. Constant one-sided application will let the dry side breathe more than the conditioned side. This can cause warping.

· Do not use edible type oils for conditioner (olive oil, vegetable, sunflower etc.) as they spoil and get rancid.

· UV light will darken all woods. It will also pull the red and purple out of the exotics and turn them brown. Do not store in direct light or in a very naturally lit room as this will darken the woods rapidly and the exotics will lose their luster and color.

· To clean, scrub with hot soapy water without submerging, rinse and towel dry.

· Let dry for a few hours in a rack or on its side standing up.

· It is best to store in a perfectly flat area or standing it up on its side to prevent warping. If left lying flat it is best to have feet on the board so both sides can breathe.

· Store in a low light area.

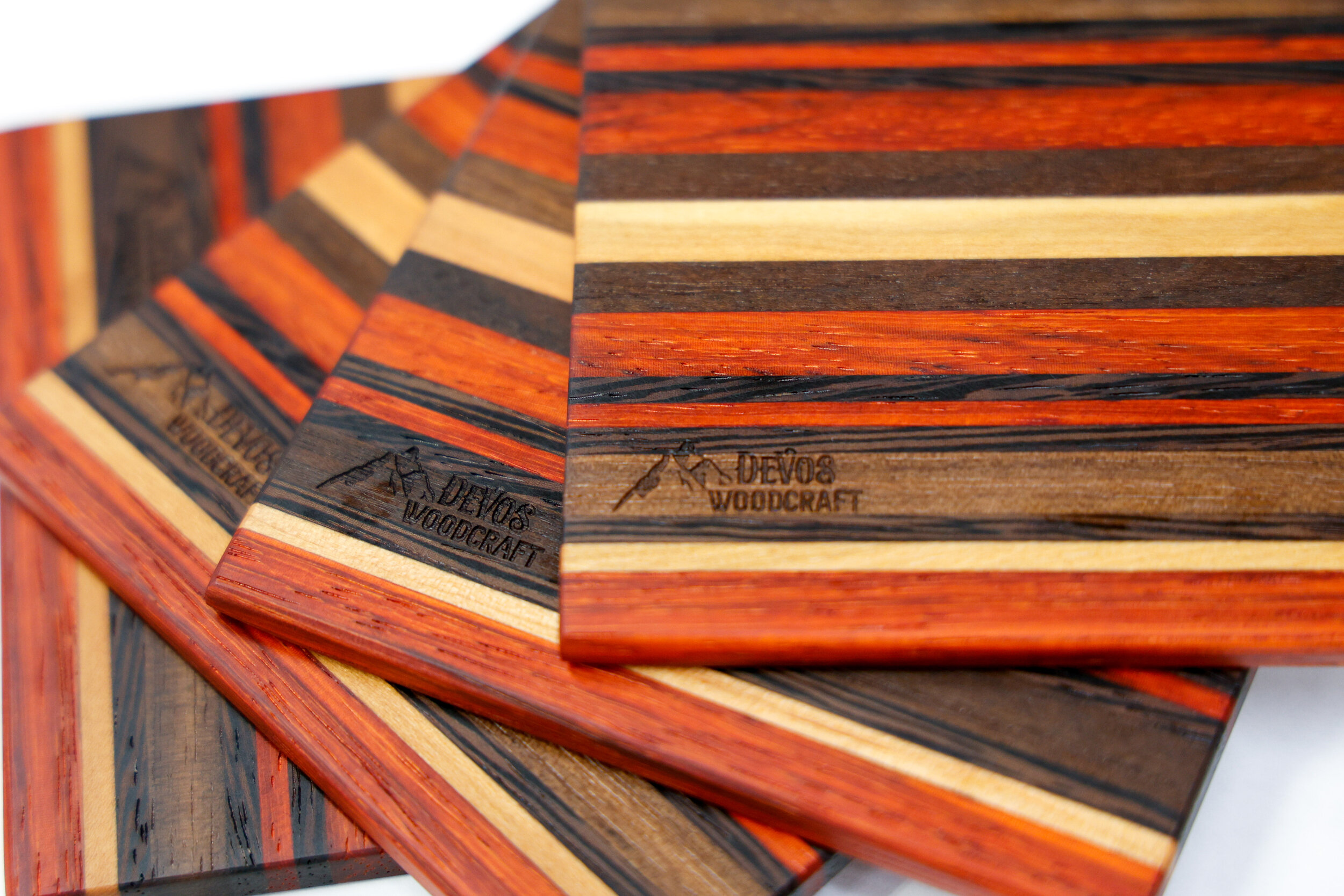

Disclaimer for the types of woods used

Exotic woods used are primarily Padauk, Wenge and Purple Heart. Just like Walnut with its slight chance of a reaction for people with nut allergens, there is a very small chance for people to have some irritant issues with the Exotic woods. Plenty of domestic woods can cause similar irritant issues.

Wood workers are exposed to the woods in the form of sawdust, which is exponentially more than using a cutting board.

These woods are more porous than some of the domestic woods like Maple and therefore require more care. Use the board conditioner frequently to keep the board as water resistant as possible.

The board conditioner also helps the wood from becoming dry and preventing splinters. This is needed for all woods but primarily Wenge which can be really sharp if the board is not maintained.

DeVo’s WoodCraft cutting boards as “Functional Art”

Most of the woods used are exotic woods, to aid in my artistic type designs. These woods are not “best case scenario” for heavy duty use. A full block of Maple, Walnut or even Cherry has been and is the standard in boards and blocks for commercial heavy duty use. Most of my boards are not made for commercial type use.

At some point I do plan on making some visually appealing end grain blocks that will be great for heavy duty/ commercial use without some of the exotic woods.

Edge Grain vs End Grain

Edge grain is less of a process to make than an end grain board. The wood fibers standing on end in an end grain board give it a harder surface that will reduce the knife marks compared to an edge grain board.

Edge grain boards can be very visually appealing because of the direction the grain runs . Edge grain boards soak up less oil/ conditioner and also less liquid during the use of the board. End grain boards need more oil and care to keep them water resistant because the fibers standing on end act as a straw to draw the moisture into the wood.

Both end grain and edge grain are great in their own ways. For heavy duty use, an end grain board can be more desired.

Exotic Woods and long term color.

The bright and vibrant color of the Purple Heart (purple) and Padauk (red/orange) will not last forever. Like all woods, they darken and change overtime with exposure to light (UV). Products containing some of these exotic woods need to be stored in a place that is not well lit by natural light.

If a board is placed in direct sunlight it can turn dark and lose its vibrant color fast, within months.

I have boards that are over 7 years old and look almost as good as the day they were made. Some of which have been out on display in the house for years, but in a dimly lit area.

I hope to offer refinishing services for a small cost in the future for those boards that need it.

Coaster Care

· Coasters are designed as decorative pieces

· Not meant for heavy condensation

· Please read cutting board care guide

The food grade board conditioner is meant to repel

water to protect the wood from swelling and cracking.

Bowl Care

Taking care of a wood bowl is pretty easy. Here are a few steps to get the most out of it.

Please display/store out of direct light. The sun will fade and damage the wood. Laminated bowls/products with exotic woods really need to stay out of areas that have a lot of natural light.

Never - soak a bowl in water, use as a hot plate, put in the dishwasher or microwave.

Solid wood bowls will stand a little more abuse, moisture and sunlight than laminated bowls.

Food Grade

After use, rinse with warm water and soap. Promptly dry with a soft cloth as much as possible. Let bowl

air dry before re-applying DeVo's WoodCraft board conditioner or similar food grade conditioner/oil.

NON Food Grade

To keep NON food grade bowls from drying out, use Natural Danish oil (found in the big box stores)

or buff with DeVo's WoodCraft board conditioner or similar food grade conditioner/oil.

The food grade board conditioner is meant to repel water to protect the wood from swelling and cracking.